The Jute Industry

The Jute Industry

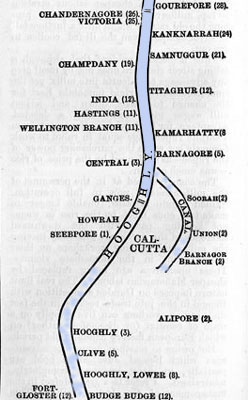

The Jute Industry: The jute mills were centered around Calcutta mainly because of the availability of raw materials. The first jute mill in Bengal started in 1855. The number of mills grew slowly to 64 by World War I. Yet this industry still provides a livelihood to more than 250,000 mill workers and more than 4 million farmers’ families. It is a golden bond with the Earth, Its use is a statement about ecological awareness as it is a fully bio-degradable and eco-friendly fibre. It comes from the earth, it helps the earth and once its life is done it merges back into the earth.

Jute Industry after 1947

Jute Mills concentrated on both sides of Hoogly river in 1894

Jute trade Jute trade is currently centered around the Indian subcontinent. Bangladesh is the largest exporter of raw jute, and India is the largest producer as well as largest consumer of jute products in the world. The local price of Jute Goods in India is the international price

. Nearly 75% of Jute goods are used as packaging materials, burlap (Hessian), and sacks. Carpet Backing Cloth, the third major Jute outlet, is fast growing in importance. Currently, it consists of roughly 15% of the world’s Jute goods consumption. The remaining products are carpet yarn, cordage, felts, padding, twine, ropes, decorative fabrics, and miscellaneous items for industrial use. Jute has entered the non-woven industry as it is one of the most cost effective high tensile vegetable fibre. Therefore, the demand for Jute has made its way into the automotive industry. Jute is now being used to manufacture more eco-friendly interiors for cars and automobiles.

Students / Parents Reviews [10]

It was good as the experience because as we had come here we had been improved in a such envirnment created here.Extra is taught which is beneficial for future.

Eshan Arora

8thBeing a parent, I saw my daughter improvement in her studies by seeing a good result in all day to day compititive exam TMO, NSO, IEO etc and as well as studies. I have got a fruitful result from my daughter.

Prisha Gupta

8thAbout Abhyas metholodology the teachers are very nice and hardworking toward students.The Centre Head Mrs Anu Sethi is also a brilliant teacher.Abhyas has taught me how to overcome problems and has always taken my doubts and suppoeted me.

Shreya Shrivastava

8thMy experience was very good with Abhyas academy. I am studying here from 6th class and I am satisfied by its results in my life. I improved a lot here ahead of school syllabus.

Ayan Ghosh

8thA marvelous experience with Abhyas. I am glad to share that my ward has achieved more than enough at the Ambala ABHYAS centre. Years have passed on and more and more he has gained. May the centre flourish and develop day by day by the grace of God.

Archit Segal

7thIt has a great methodology. Students here can get analysis to their test quickly.We can learn easily through PPTs and the testing methods are good. We know that where we have to practice

Barkha Arora

10thIt was a good experience with Abhyas Academy. I even faced problems in starting but slowly and steadily overcomed. Especially reasoning classes helped me a lot.

Cheshta

10thOne of the best institutes to develope a child interest in studies.Provides SST and English knowledge also unlike other institutes. Teachers are co operative and friendly online tests andPPT develope practical knowledge also.

Aman Kumar Shrivastava

10thI have spent a wonderful time in Abhyas academy. It has made my reasoning more apt, English more stronger and Maths an interesting subject for me. It has given me a habbit of self studying

Yatharthi Sharma

10thMy experience with Abhyas is very good. I have learnt many things here like vedic maths and reasoning also. Teachers here first take our doubts and then there are assignments to verify our weak points.